2016 Boiler Rebuild for the SP&S 700

The 15-year boiler rebuild is a massive and complicated undertaking. Let's break it down...

A Brief Primer on Locomotive Boilers

The boiler of a steam locomotive is no different than any other boiler, except that it is on wheels. The basic design of a boiler includes a shell (the outside), tubes (pipes that run through the boiler), tube sheets (the end-plates of the boiler that hold the ends of the tubes), and a firebox. The tubes running through the boiler transfer heat from the flue gas exiting the firebox to the water contained within the boiler, producing steam. On a locomotive, the firebox is suspended within the boiler by stay bolts and surrounded by water. Below is a schematic showing the 700's boiler, firebox, and smokebox:

This schematic of the SP&S 700's boiler, firebox, and smokebox shows the path

that the steam takes from boiler to dry pipe to superheater header to superheateers to throttle bottle to steam chest. Drawing by Jeremy Klitzke © 2016 for the PRPA.

This schematic of the SP&S 700's boiler, firebox, and smokebox shows the path

that the steam takes from boiler to dry pipe to superheater header to superheateers to throttle bottle to steam chest. Drawing by Jeremy Klitzke © 2016 for the PRPA.

So Why Rebuild the Boiler?

Boiler explosion on Southern Pacific 4-8-4 Class GS-1 #4402.

The boiler of the SP&S 700 isn't broken, but it is due for a periodic inspection so thorough that it requires a complete dissassembly and rebuild. The Federal Railroad Administration requires this inspection every fifteen years or 1472 service days, whichever comes first, (see "Steam Locomotive Inspection and Maintenance Standards," CFR49 Part 230). The inspection entails a meticulous examination of every rivet, plate, and seam of the boiler shell as well as a painstaking ultrasonic thickness survey of all the boiler's important components. The purpose of the inspection is to to ensure the public safety by verifying that the locomotive boiler remains sound and capable of containing the amount of steam pressure it generates. In the case of the 700, this is 260 pounds per square inch. The inspection process is important because a boiler explosion ain't pretty and usually kills or injures anyone nearby. The inspection incorporates all elements of the pressure vessel, including the boiler shell, the firebox walls, boiler flue tubes, superheaters, flue sheets, and all the various stays and supports within the boiler. In addition to all the mandated work on the pressure vessel, the rebuild is also a good time to go over all the other plumbing that is usually inaccessible.

Steps of the Rebuild

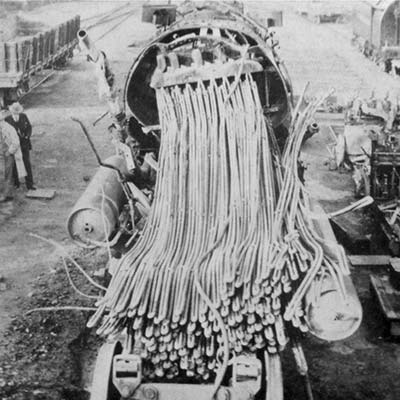

Walt Eisenman hefts the next tube to be stuffed back into the 700 at Brooklyn Roundhouse during the last rebuild in 2000. Photo by Dale Birkholz.

The basic nuts and bolts of a 15-year boiler inspection include the following tasks:

- Remove all the gauges, valves, and piping from the cab.

- Remove the brick from the firebox.

- Remove all the jacketing (the shiny metal wrapped around the boiler) and lagging (the insulation under the jacketing).

- Open the smokebox door and remove the blower nozzle (steam jet that aids in creating draft),the blastpipe (where steam is exhausted from the cylinders), and the petticoat pipe (which guides the steam from the blower and blastpipe out the smoke stack).

- Remove the superheaters.

- Remove the boiler flue tubes. Note: Removing a tube is a destructive process, so any taken out must be replaced.

- Clean out the smokebox, clean the flue sheets, and clean the boiler shell inside and out.

- Inspect all parts that have been removed and repair or replace as necessary.

- Inspect all of the plumbing that leads to the various steam or air operated appliances that are on or around the boiler, as well as the gadgets themselves. Repair or replace as necessary.

- Visually inspect the boiler shell inside and out (including all rivets and seams), inspect all braces and stays, inspect the flue sheets inside and out, and inspect the firebox walls and stay bolts.

- Ultrasound the boiler shell, flue sheets, and firebox walls and document their thicknesses.

- Reinstall tubes and superheaters.

- Pressure test the boiler and check for leaks.

- Reconnect all the various appliances on and around the boiler.

- Reinstall jacketing and lagging (requires new lagging).

- Reinstall the brick in the firebox (requires new brick).

- Reinstall gauges, valves, etc. in the engine cab.

- Start 'er up and drive off…

Easy as pie, right? Not so fast. As anyone who has ever started a project this big and complex on such an old piece of equipment will know, we are bound to find some other problem that needs to be fixed. In fact, the PRPA will actively be seeking out these "extra" problems so that we can solve them in the shop rather than out on the road.

Has the PRPA Ever Completed a 15-Year Inspection on the SP&S 700?

Yes! The PRPA successfully completed the FRA inspection on the SP&S 700 in 2001, and in fact we were the first to undertake a rebuild under the then-new rule. Click here to see our photo essay of the last rebuild. Many of the same folks that worked on the last rebuild are still volunteering with the organization, so we are confident that we have the skills to complete the job once again. Our current facility, the Oregon Rail Heritage Center, is a vast improvement over the old Brooklyn Roundhouse. All we need now is your generous support!